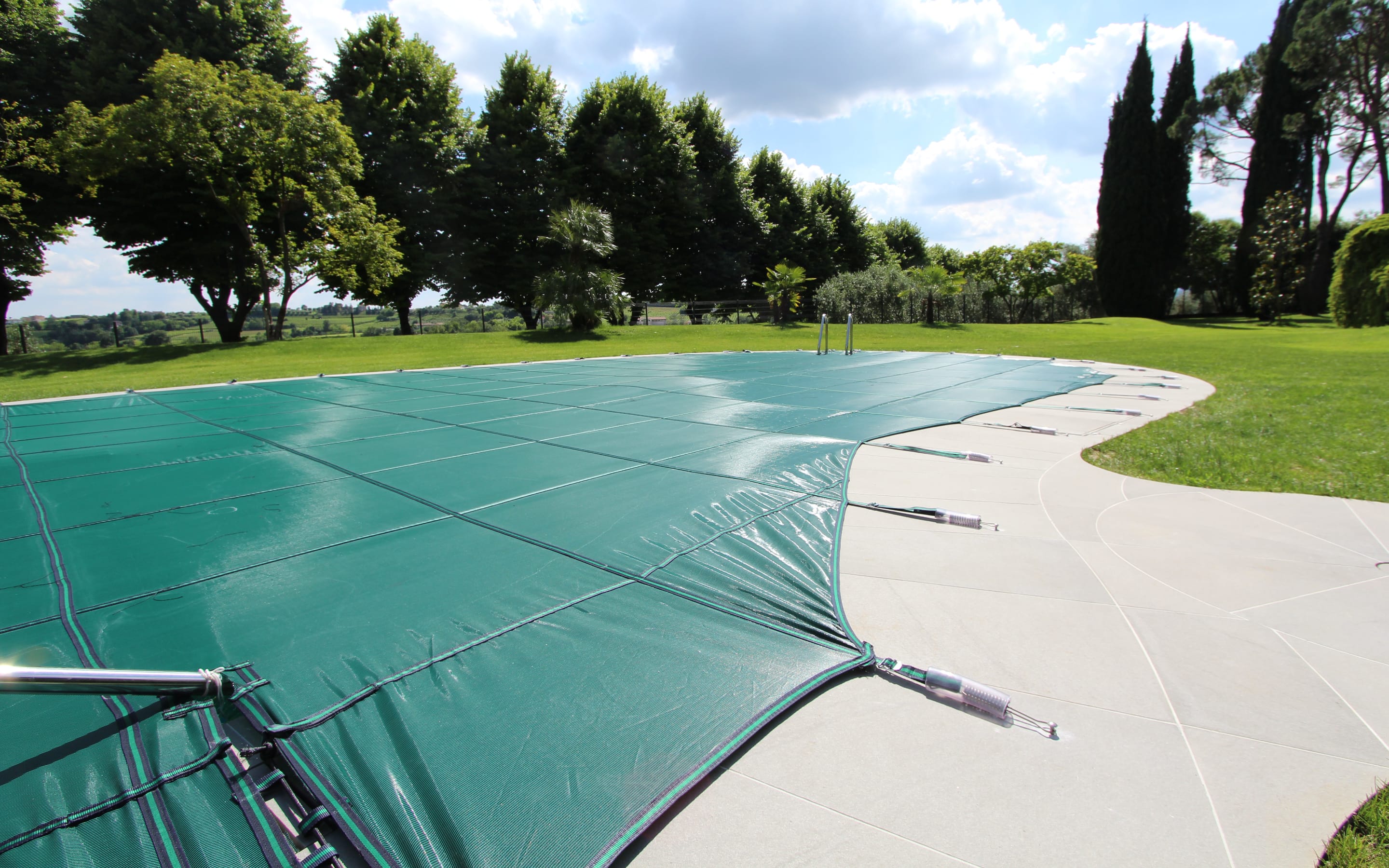

In order not to be stopped by unpredictable weather and to be able to train all year round, the ideal solution is to equip your riding arena with a roof. The best choice to achieve this in a short time and without the costs of a more demanding masonry construction are Favaretti Group's innovative riding hall tensile structures. Thanks to the first-class materials used, they are extremely robust but at the same time lightweight and easy to dismantle.

THE 3 MAIN PLUSES OF OUR RIDING HALL MARQUEES

The main benefits of installing a riding hall marquee include:

Why choose Favaretti riding arena canopies

A riding arena marquee from Favaretti Group is an ideal solution for those who wish to protect their riding arena from bad weather with a reliable, versatile and elegantly designed cover.

What Favaretti Group guarantees:

- Covered riding arenas with a light anchoring system without curbs or concrete plinths, making it easier to obtain permits.

- Canopies with free span width: they can easily exceed 50 metres without central encumbrances and ensure maximum freedom of movement.

- Tensostructures without awkward tie rods or ropes installed across the width of the pitch (unlike aluminium structures).

- Double-curved shaped roof membrane: maintains perfect stability even in very strong gusts of wind. It also avoids annoying noises inside the pitch (impossible with classic aluminium structures).

- Technical report signed by qualified engineer guaranteeing real resistance to snow, wind and seismic shocks, according to current regulations.